Features

The Kt-Pulse system has three components that work seamlessly together

Setup

(setup web app)

Capture

(data collector mobile app)

Visualise

(analytics web app)

![]()

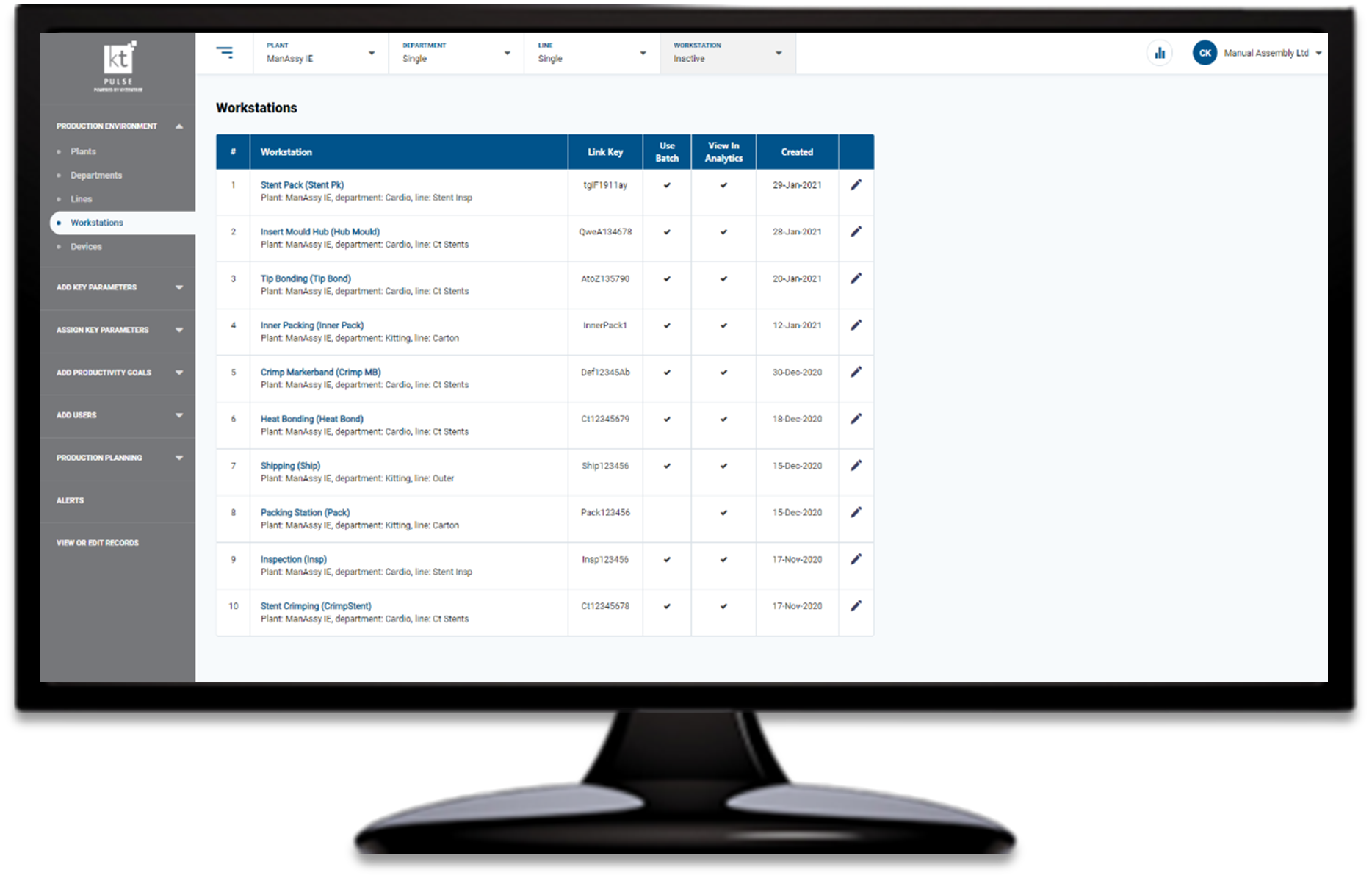

Setup

Add all of your key manufacturing parameters with a user-friendly and intuitive front end

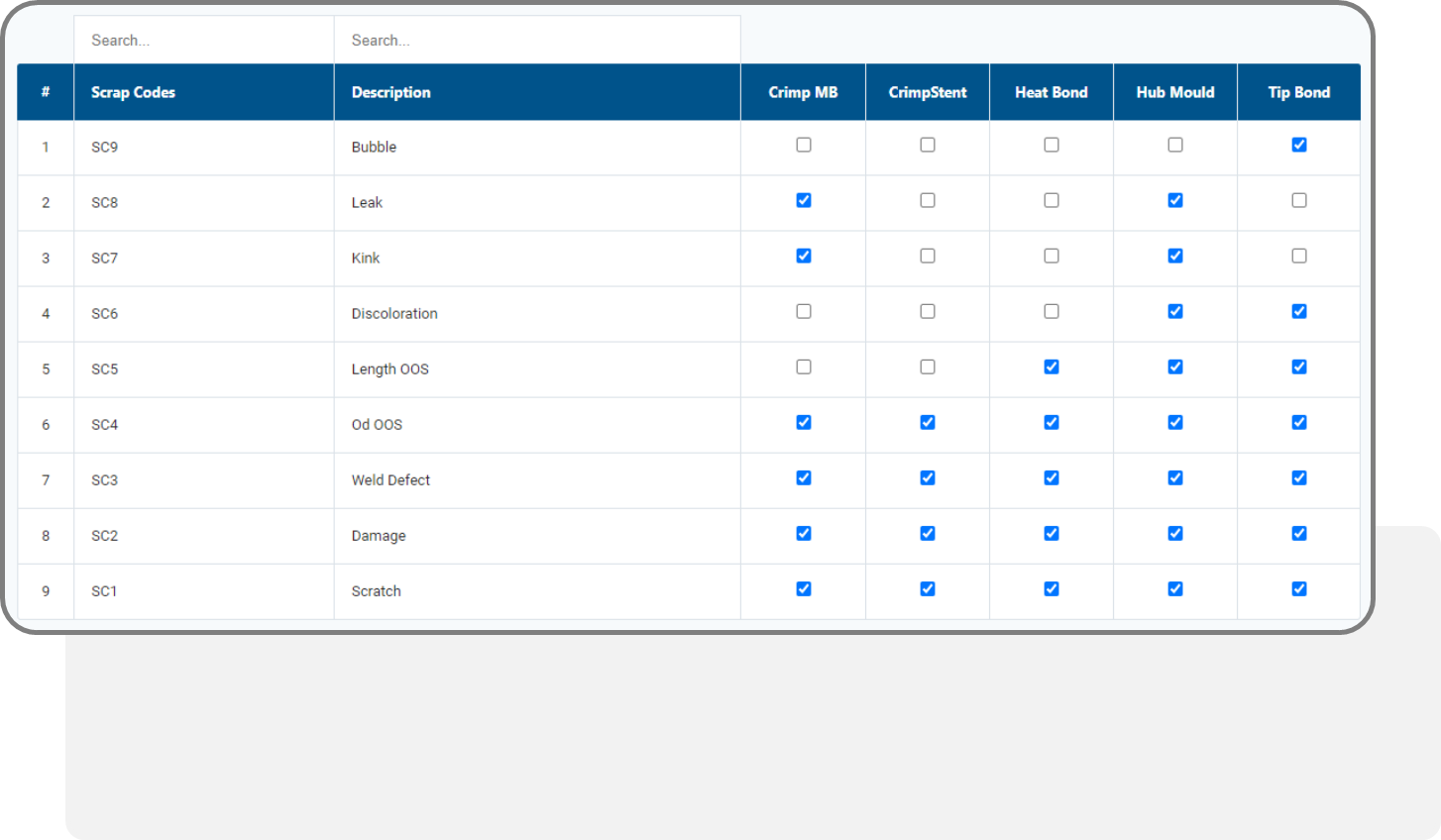

Targeted downtime and scrap reasons

Create a company-wide list of downtime and scrap codes and assign them to the relevant workstations

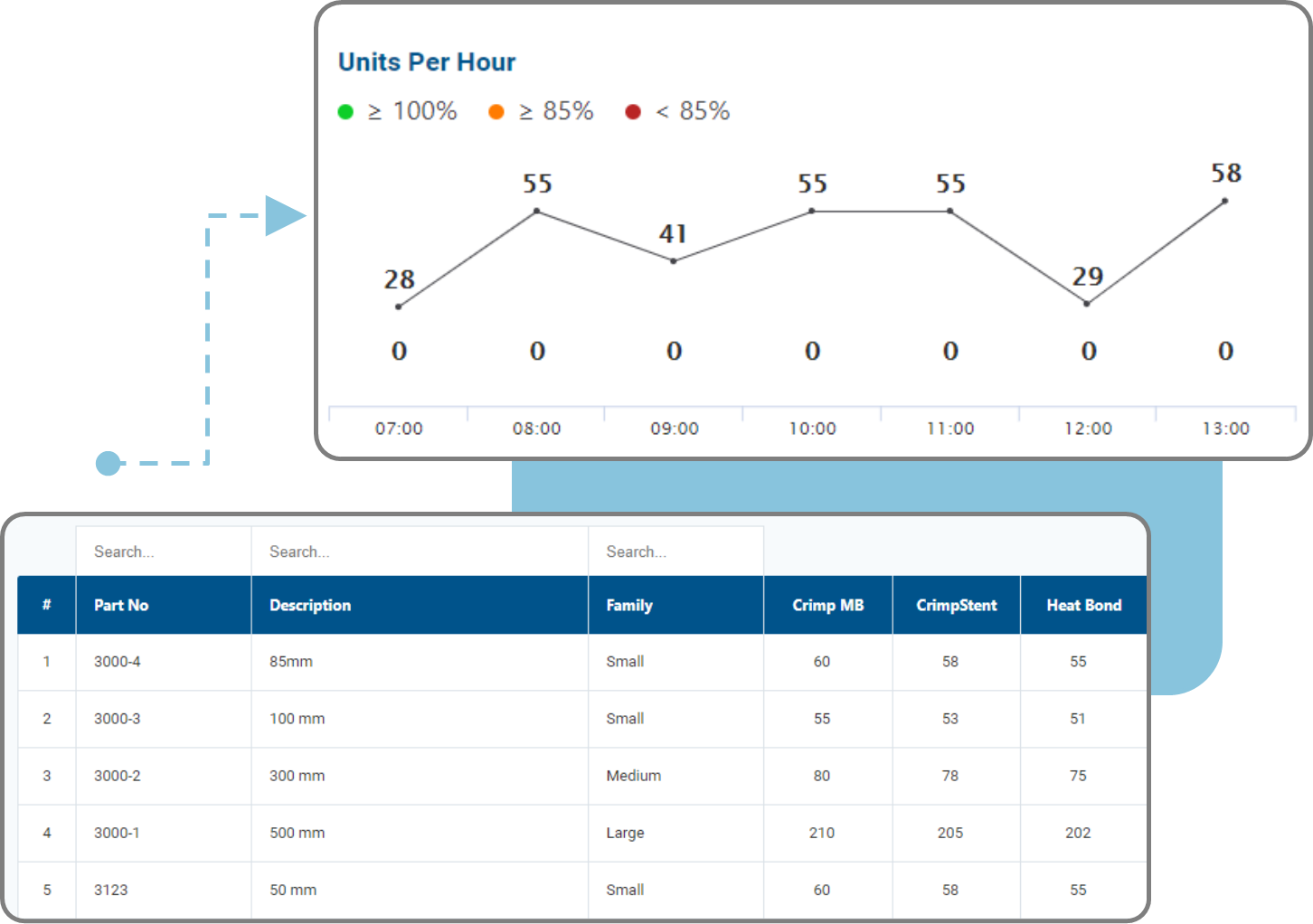

Flexible output targets

Hourly output targets automatically adjust for scheduled break times and part number selection

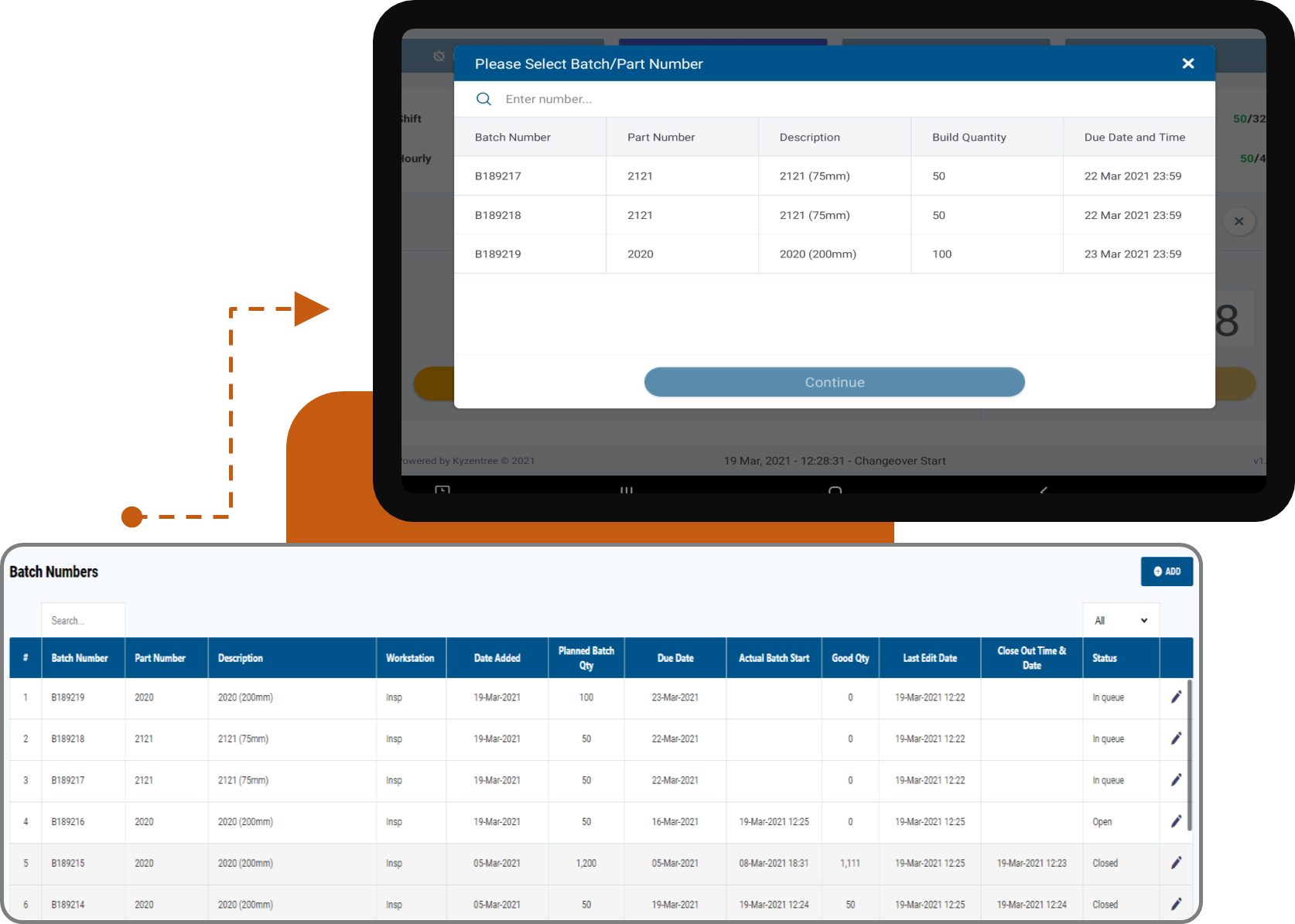

Manage production scheduling

Schedule due dates for each production batch and prioritise the order of builds assigned to the production operators

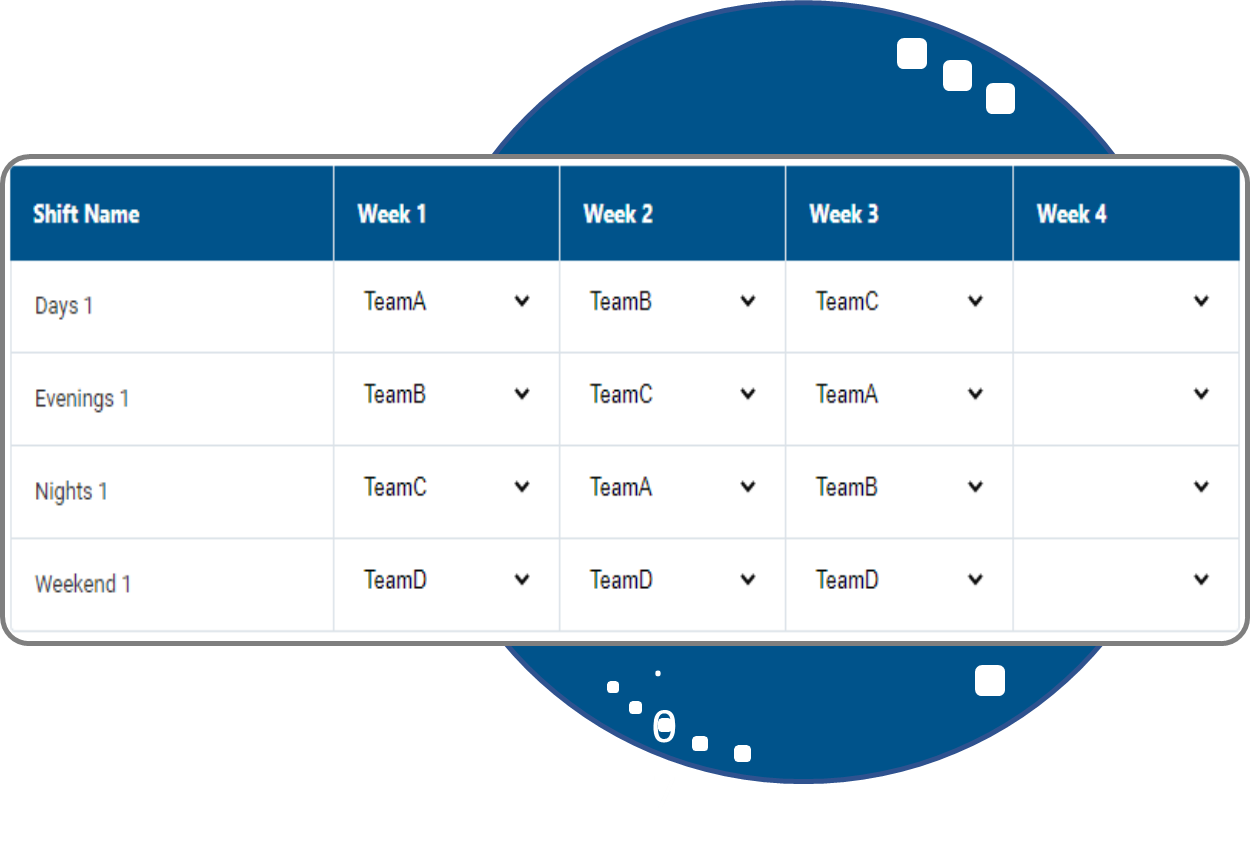

Shifts and teams

Set up shift patterns and teams to analyse all of your key performance indicators by shift or team

![]()

Capture

Production operators log good units, defects and downtime events in real time through a simple touchscreen interface

Adjustable counts

Log one or multiple good units or defects with each button press

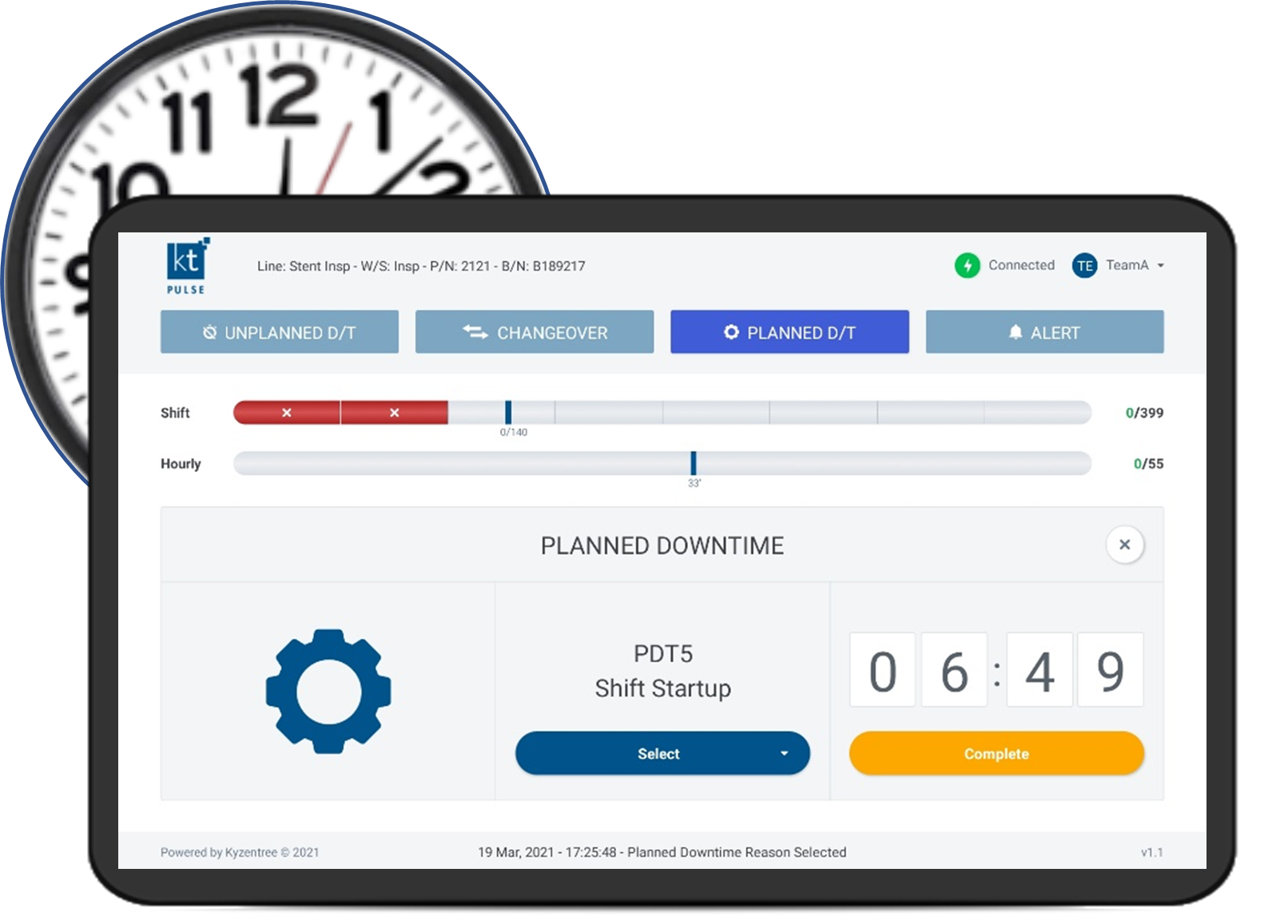

Capture lost time precisely

Log every downtime and changeover event precisely without guesstimating

Real-time productivity tracking

Production operators can see, at a glance, if they are on track to meet the output target for the current hour and shift

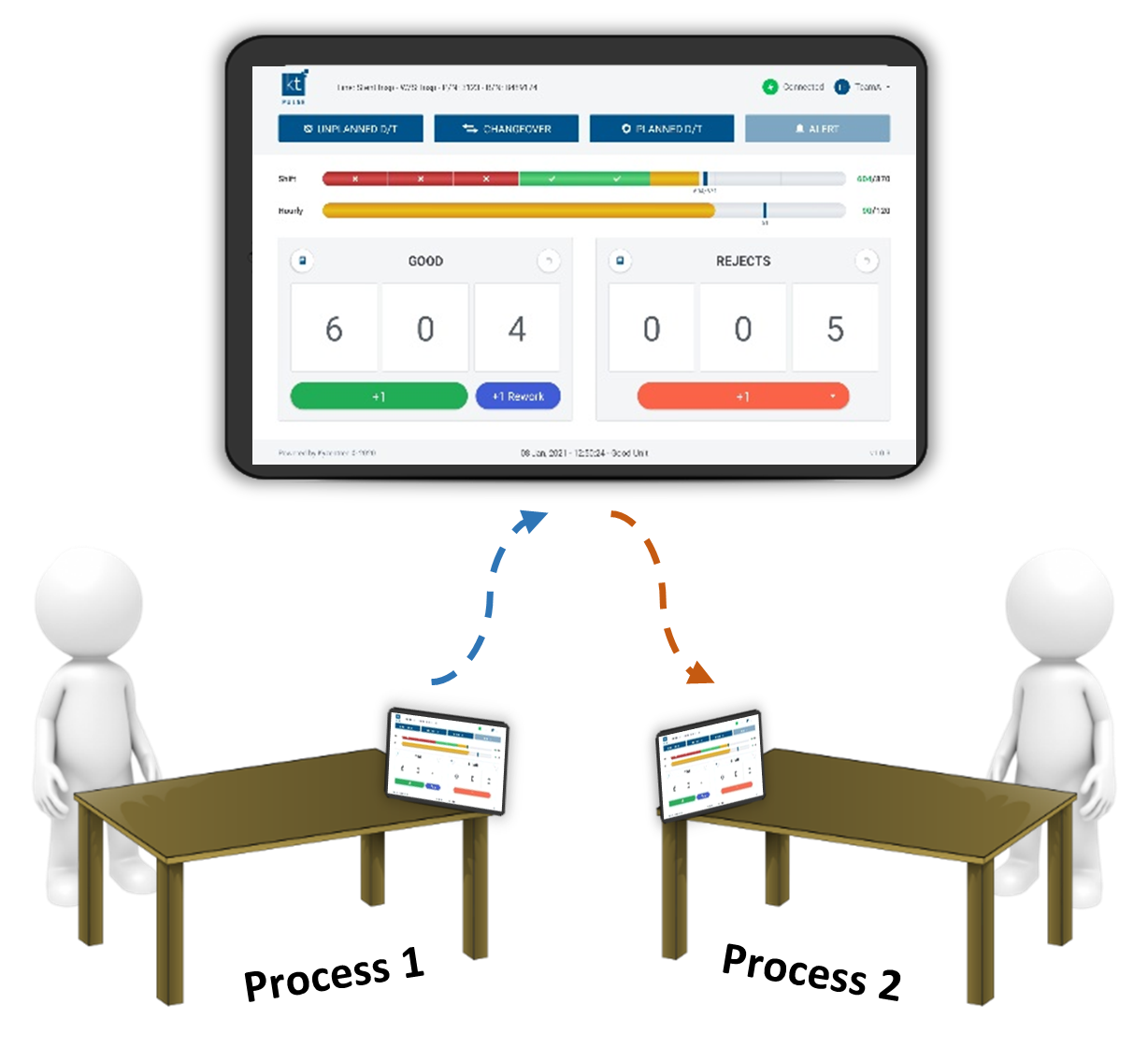

Swap the collector location

If you want to move the collector to a new process, enter the new link key and you are up and running in less than a minute

![]()

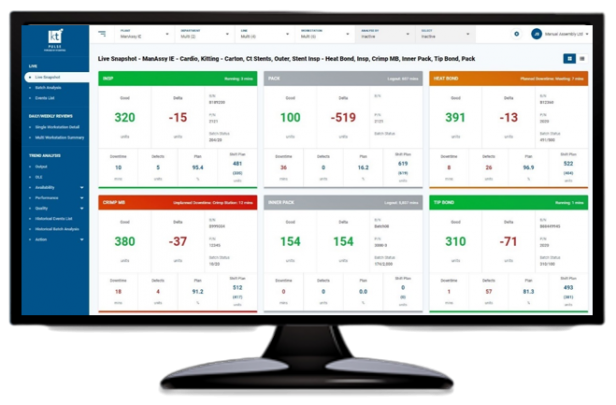

Visualise

Kt-Pulse is your visual factory tool. Keep everybody up-to-date on the production floor, in the office or remotely

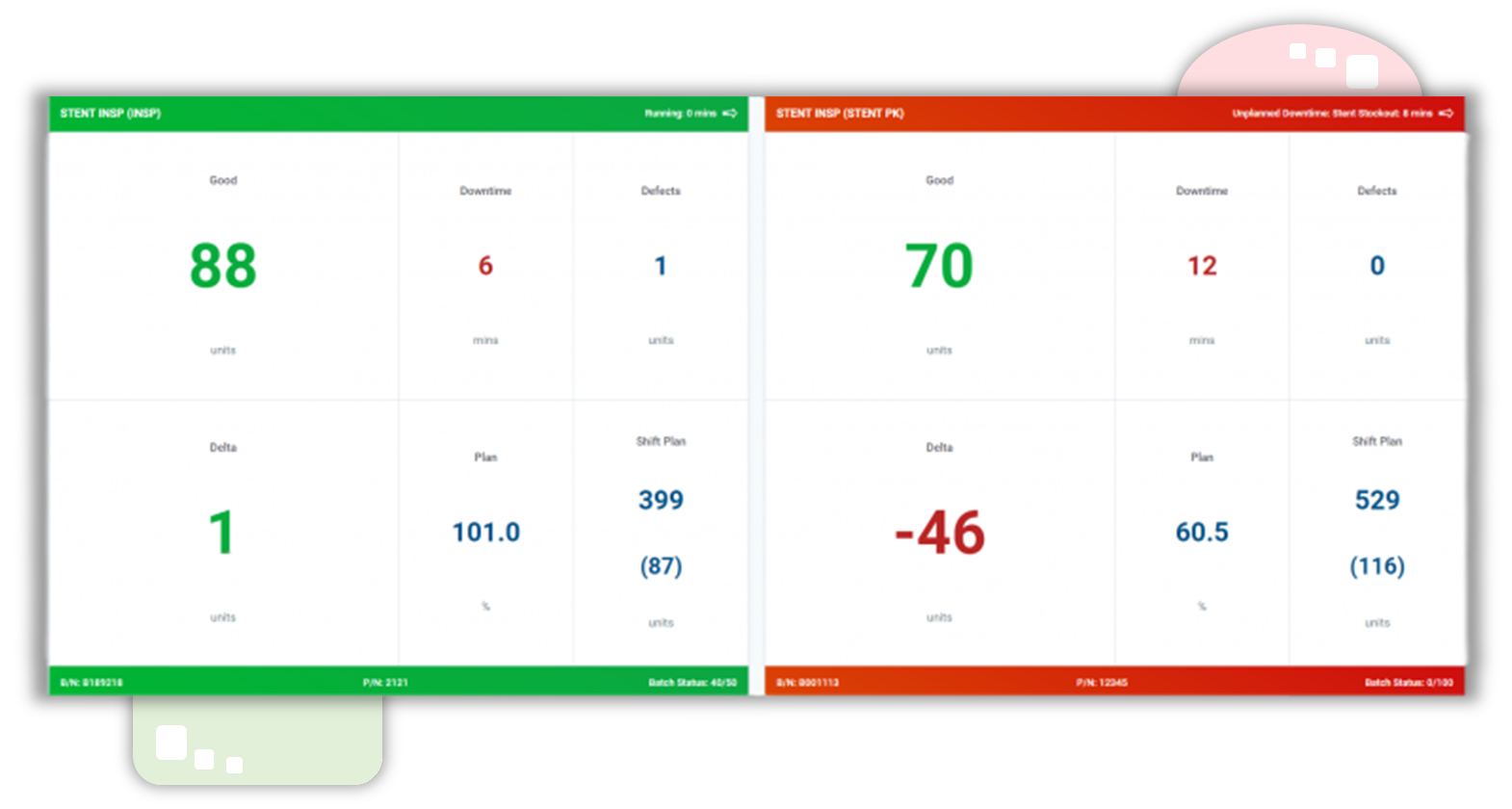

Real-time analytics

Live snapshot views that highlight if output is on track and what processes need support

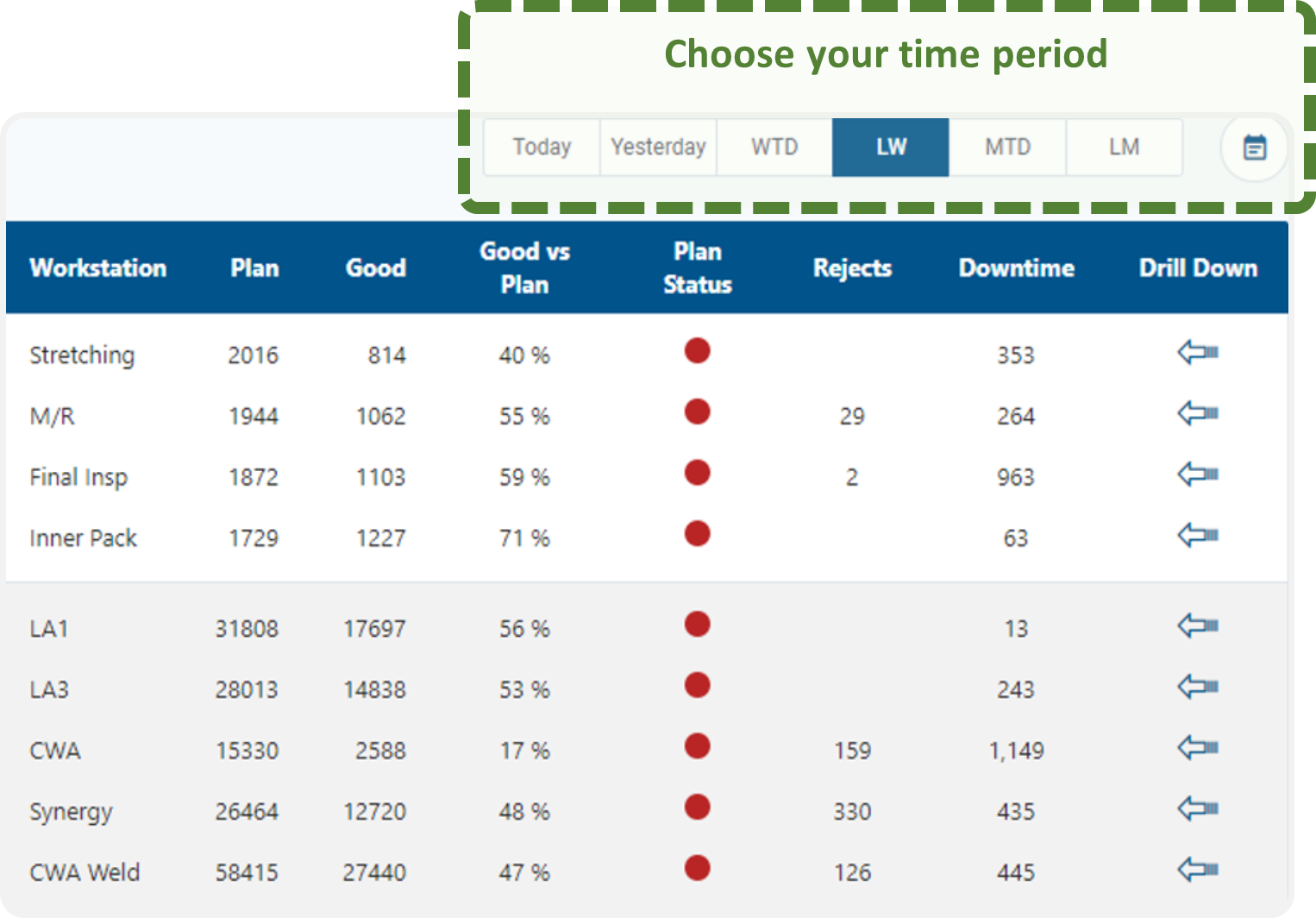

Shift summary analysis

Run more effective team meetings with accurate insights by shift, day, week or month

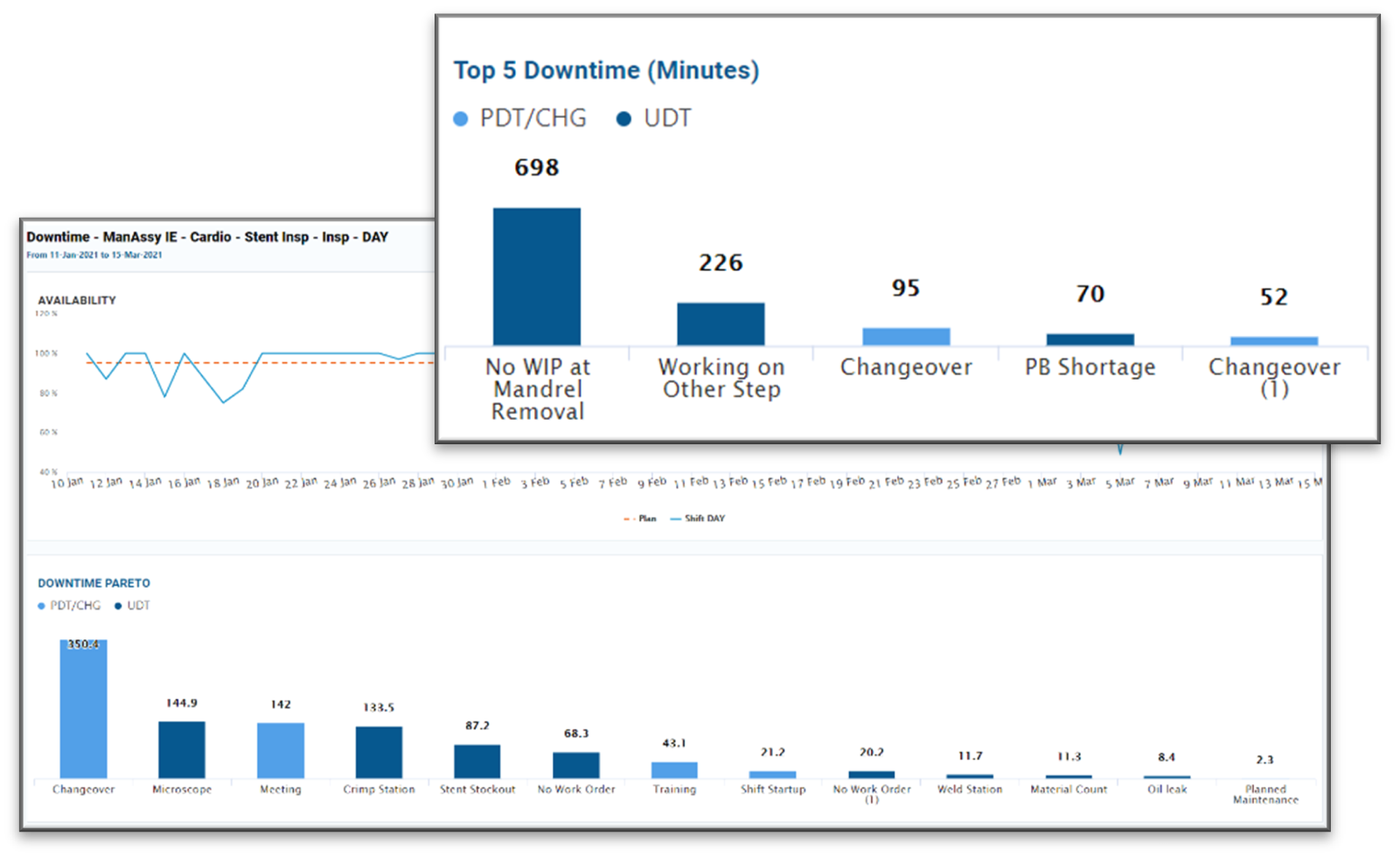

Trend analytics

Run charts and Pareto charts that help you discover where the biggest improvement opportunities exist

Drilldown

Review processes at a top level or use the drilldown function to discover deeper insights

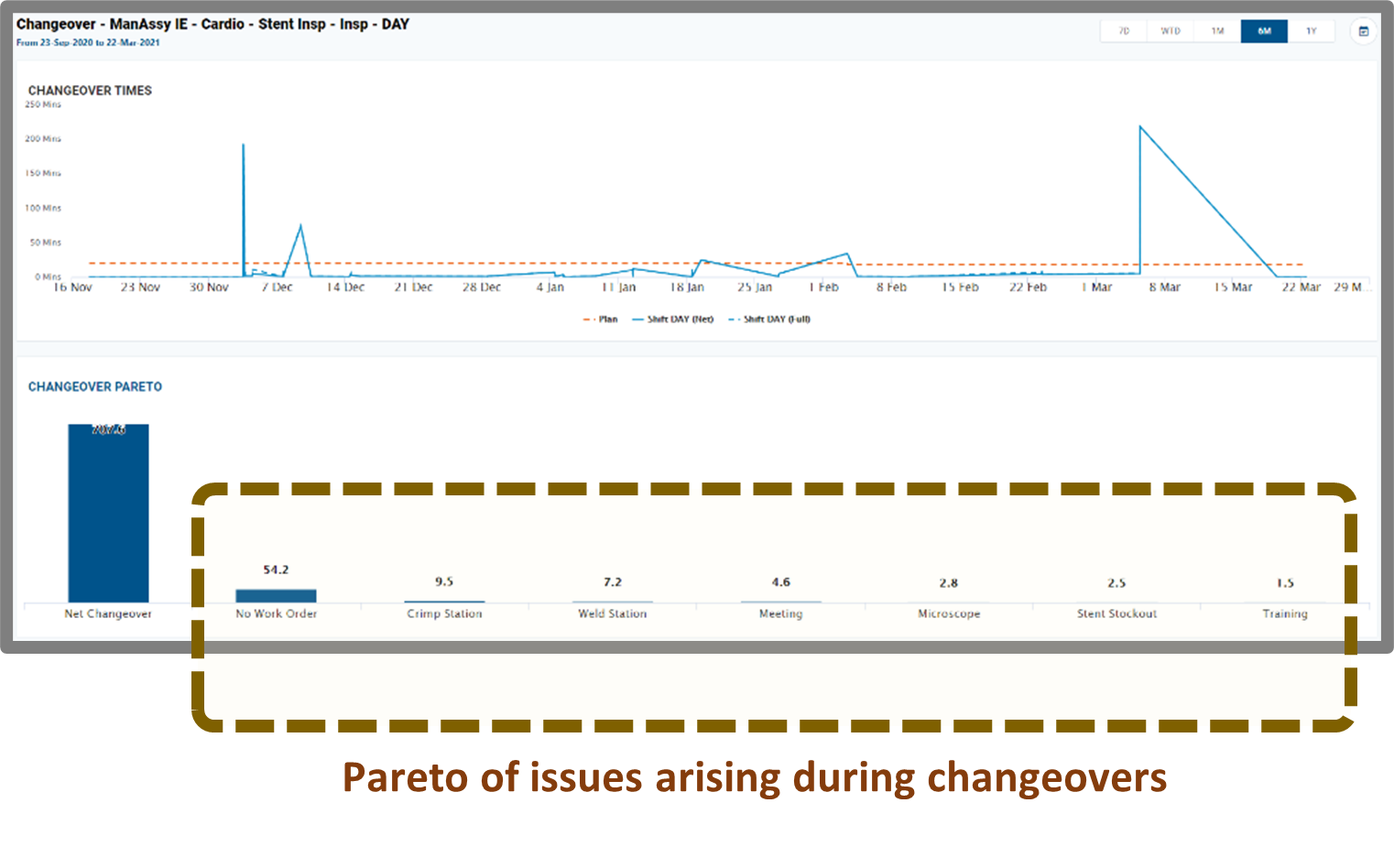

Changeover analysis

Track changeover times precisely and quantify the impact of problems that arise during changeovers

Root cause analysis

The events list summarises every logged event. A great tool for root cause analysis of downtime and quality issues

Export to CSV or Excel

Export your data to CSV or Excel to carry out further analysis

Remote access

Access all of the Kt-Pulse analytics remotely when you can’t make it onto the production floor

Kt-Pulse in numbers

Productivity

Response time

Yield